Application Location

The mixing pump as a feed pump is set up and used in a refinery plant. It is connected directly to the columns of the refinery plant via connecting flanges.

Pumping medium

The mixing pump delivers pure liquids that do not chemically or mechanically attack the pump materials. The task of the mixing pump is to transfer benzene, toluene and their derivatives between the column segments (fractions).

Mode of operation

The mixing pump is operated constantly at a fixed speed in continuous operation. Due to the design, installation site and task of the mixing pump, no high mechanical loads occur during operation.

Location

The mixing pump is installed and used directly next to the columns of the refinery in the open air. The mixing pump can be used in continuous operation under the following site conditions:

Pumped Liquid | Benzol Tuloul and other Derivate |

Temperature of pumped medium (°C) | + 60 |

Max. operating pressure (bar) | 16 |

Max. surrounding temperature (°C) | + 80 |

Max. surface temperature (°C) | < 120 |

Industries, using Mixing Pumps:

Pipeline Industry

Schäfer Pumpen & Hydraulik’s lightweight pump design means it can be easily adapted to pipelines around the world.

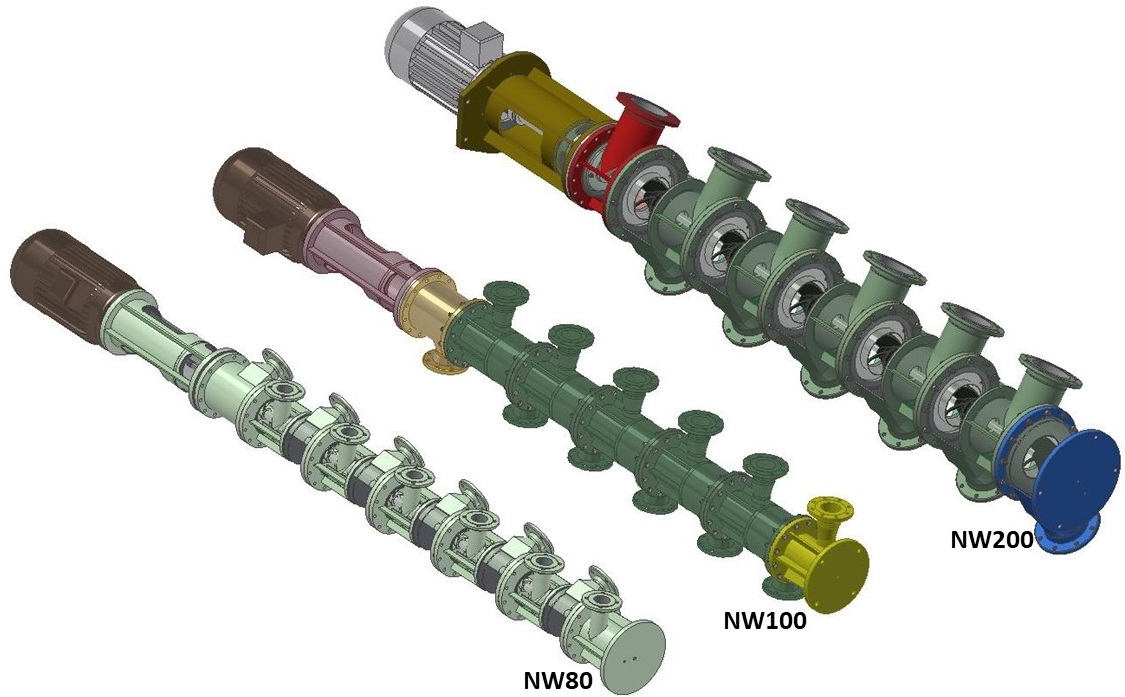

Nominal size | Max. flow rate (m3/h) | Speed (min-1) | Amount (mm) | Socket size | Motor power | |

without motor | Inlet socket | Outlet Socket | ||||

80 | 50 | 970 | 3.915 | 4" 150 lb | 3" 150 lb | 7,5 kw / 50 Hz / 1.000 min-1 |

100 | 50 | 970 | 3.930 | 4" 150 lb | 4" 150 lb | 7,5 kw / 50 Hz / 1.000 min-1 |

200 | 50 | 750 | 4.423 | DN 200 | DN 200 | 15 kw / 50 Hz / 750 min-1 |