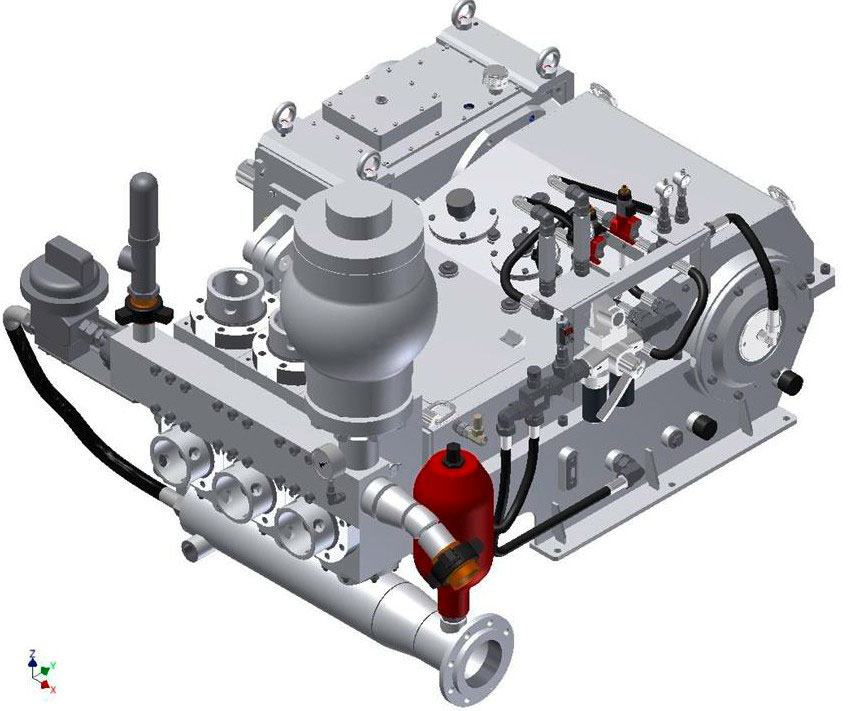

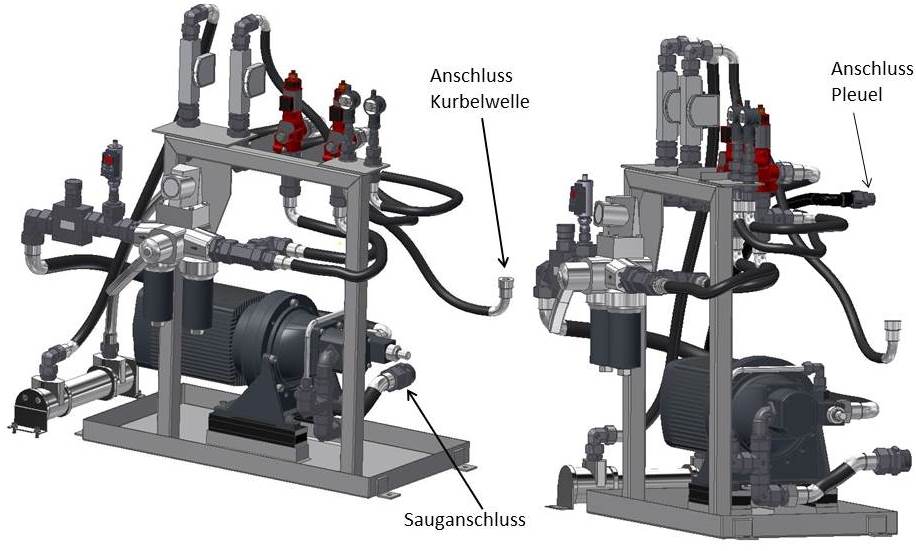

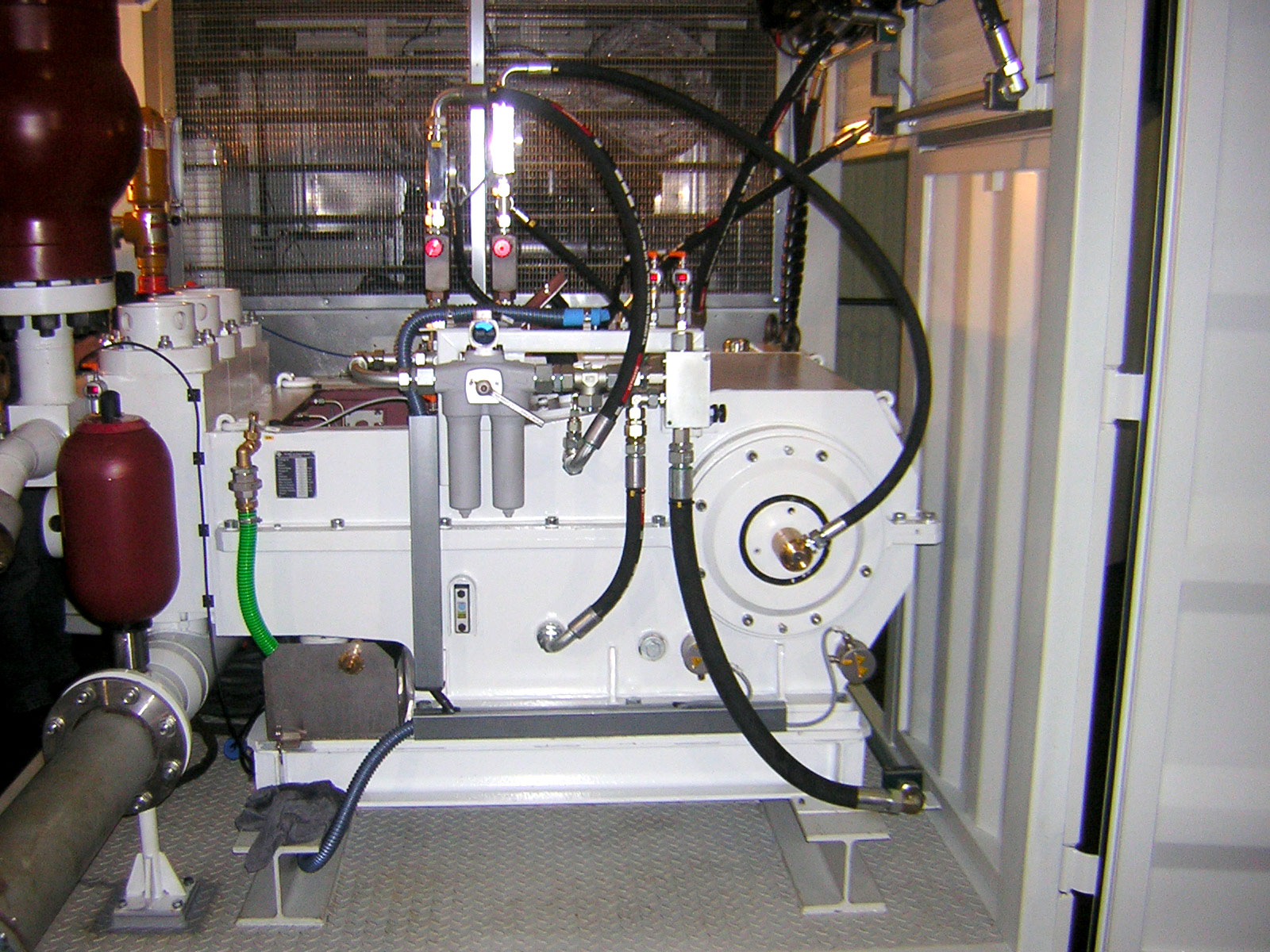

The standard engine pressure lubrication system from Schäfer PH is constructed as a separate unit which is either bolted to the pump on a frame or is connected as a separate unit via hoses.

In this case, the necessary fittings are arranged on a frame, which is attached to the pump on the drive side and connected via hoses to the pump connections provided for this purpose. It consists of a gear pump driven by a motor (electric motor / hydraulic motor, or from the auxiliary drive of a diesel engine: drive lubrication unit) completely assembled with bellhousing, coupling and damping rails. To control the outgoing pressure, the lubricating oil pump requires a pressure relief valve preset to 15 bar. The two connection points crankshaft inlet and connecting rod bearing require a quantity of approx. 20l/min each, which should be ensured by control valves.

The fittings of the two lubrication lines are mounted on a console. The components are connected to each other and to the pump by means of piping and high-pressure hoses.

Existing (required) monitoring

Component | Parameter | Value |

Pressure oil lubrication crankshaft | Inlet temperature | |

Inlet pressure | max. 16 bar | |

Flow rate | max. 40l / min | |

Pressure oil lubrication connecting rod | Inlet temperature | |

Inlet pressure | max. 16 bar | |

Flow rate | max. 40l / min |

Our special products and accessories:

SUMO Monitoring-System

Schäfer Pumpen & Hydraulik’s innovative automatic monitoring system for piston pumps is a highly sophisticated and very reliable maintenance tool.

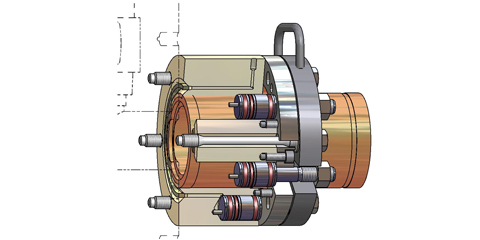

Hydraulic Tensioning Device

Schäfer Pumpen & Hydraulik has developed an innovative, fully hydraulic tensioning device for the rapid replacement of worn mud pump liners and valves